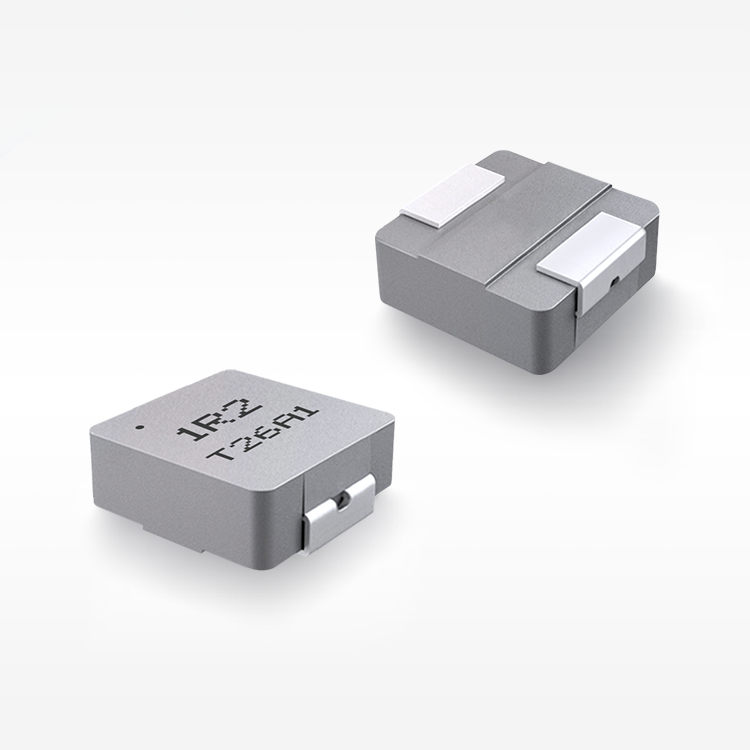

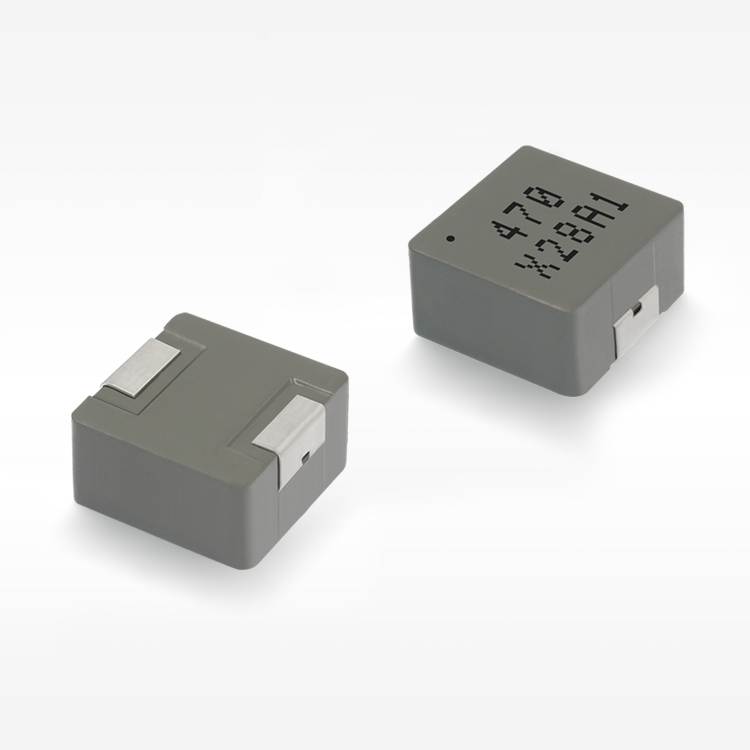

molding power choke for communication

It’s a high tech electronic component capable of processing electric power that was originally created for the adaptors of the communicating electron tubes, then developed to the regulator tubes themselves. Its main functions include filtering out high frequency noise, which may increase effective values by tens of milliamperes, stabilising voltage for transistor amplifiers, and preventing damages to sensitive electronic components. Technological highlights of the molding power choke include its small size; high current saturation (how much it can take before magnetic material becomes saturated); low DC resistance; and good temperature stability in different contexts. Such features mean that it is universally adaptable, being suitable applied to a wide range of devices from minicomputers and mobile terminals through network infrastructure equipment up to nuclear power stations--where needless interference must be avoided.