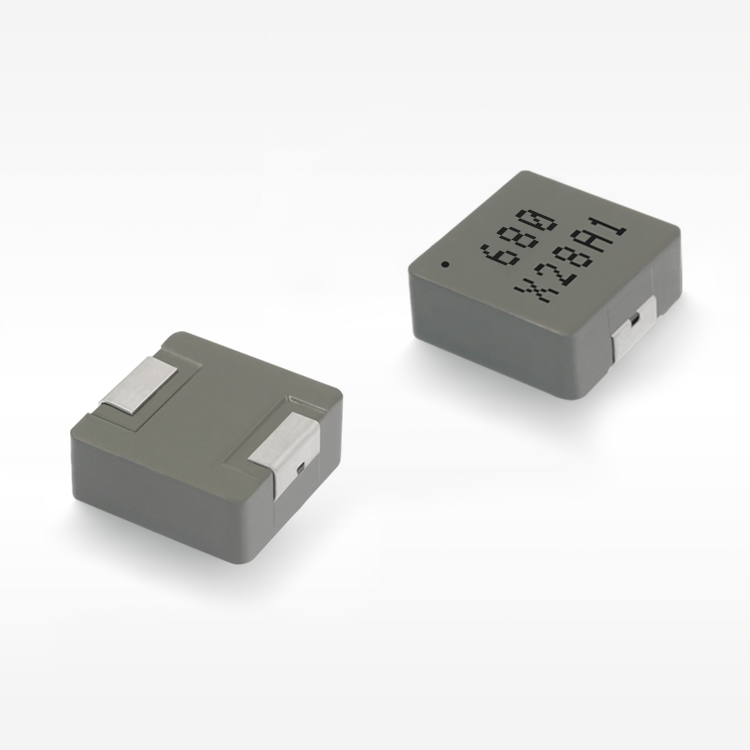

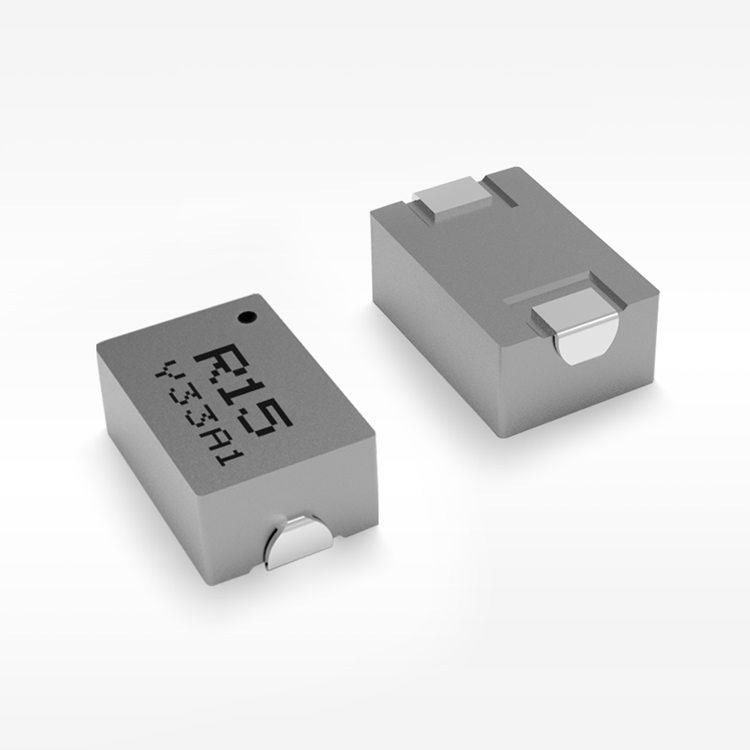

high current molded power inductor

High current molded power inductors represent a critical component in modern electronic systems, designed to handle substantial electrical loads while maintaining exceptional performance and reliability. These sophisticated electromagnetic devices serve as energy storage elements that regulate current flow, filter electrical noise, and provide stable power delivery in demanding applications. The high current molded power inductor combines advanced magnetic core materials with precision-wound copper conductors, all encased in a durable molded housing that ensures optimal thermal management and mechanical protection. The molding process creates a compact, robust structure that can withstand harsh operating conditions while delivering consistent electrical characteristics. These inductors utilize ferrite or powdered iron cores that have been carefully engineered to minimize power losses and maximize energy efficiency. The molded construction provides superior moisture resistance, vibration tolerance, and temperature stability compared to traditional open-core designs. High current molded power inductors typically handle currents ranging from several amperes to hundreds of amperes, making them ideal for power conversion circuits, DC-DC converters, voltage regulators, and motor drive systems. Their low DC resistance minimizes power dissipation, while their optimized inductance values ensure proper energy transfer and filtering capabilities. The compact form factor allows for high-density circuit board layouts, enabling designers to create more efficient and space-saving electronic products. Manufacturing processes involve precise winding techniques and automated molding procedures that guarantee consistent quality and performance across production batches. Quality control measures include electrical testing, thermal cycling, and mechanical stress evaluation to ensure each high current molded power inductor meets stringent industry standards for automotive, industrial, telecommunications, and consumer electronics applications.