Resistentia Humilis pro Efficaci Energiae Transitu

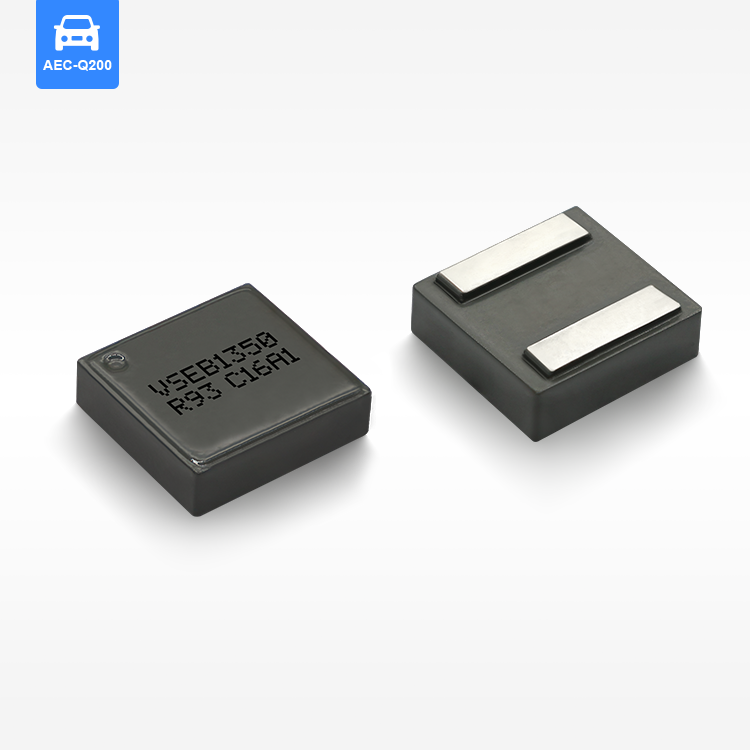

Cum accumulatio energiae magneticae augendam fluxum magneticum requirat, plures ferritae terminaliter convolutae adhibentur ad permittere altiores frequentes, ita meliorem regulationem copia energiae praebendo. Ita nullae sunt gravia effecta addendo plures convoluciones vel augendo inductantiam, quae in figura 3.14 ostenditur: Haec est inclinatio parallela cum illa modo in Fig 96 demonstrata! Ut in Fig.2A, Fig 2B, systemata moderandi motores transferendi sunt quae postulationem installationis ducis ad systemata specialia moderandi motores transferunt. Quod ad consequens, hi inductores potentiae altae currentis adiuvant ad efficiendum magis efficacem transferentiam energiae in systematibus moderandi motores: causant ut caloris emissio minor sit. Minor amissio potentiae et melior perficiendi thermalis bonum est ad stabilitatem componentis electronicorum maxime criticorum et cum longo tempore sequendi, spectans haec beneficia in vicem adiuvabit tuam productionem TLC in linea ad requisita bureau. Energia quae non amittitur ad ambitum etiam sumptus usus energiae et pollutionis minuit, multum conferens ad amicae ambitus facilitatem. Hoc significat quod eligens id ut partem principalem pecuniam et faciem in futuris terminis servabit.