Introduction: Core Role of Inductors in Digital Amplifiers

Inductors are crucial components in digital amplifiers, playing a core role in energy management and signal stability. By storing energy in a magnetic field when current flows through them, inductors provide efficient energy storage solutions essential for the smooth functioning of digital amplifiers. This capability enables them to support and smooth out ripple currents, which contributes to more stable voltage levels and prevents signal distortion—an essential aspect in maintaining audio clarity. The energy storage capacity of an inductor is quantified by its inductance value, measured in henries. This value significantly influences the performance and efficiency of the amplifier circuits by affecting how they manage energy and react to changes in current flow.

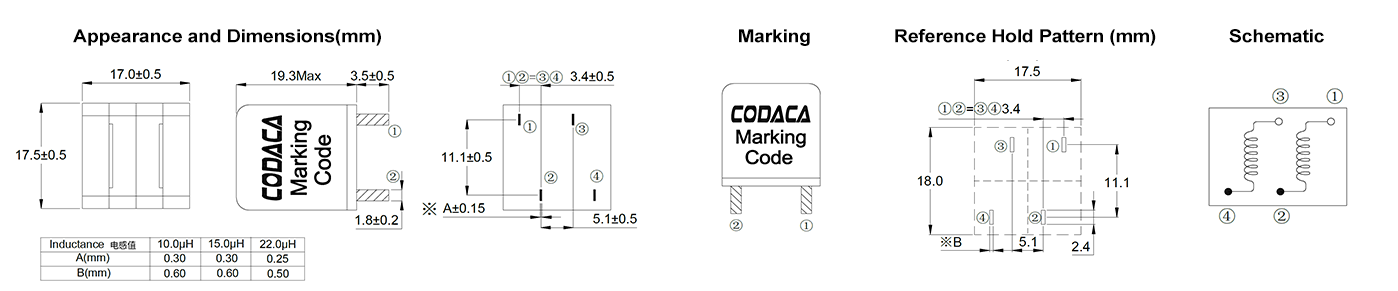

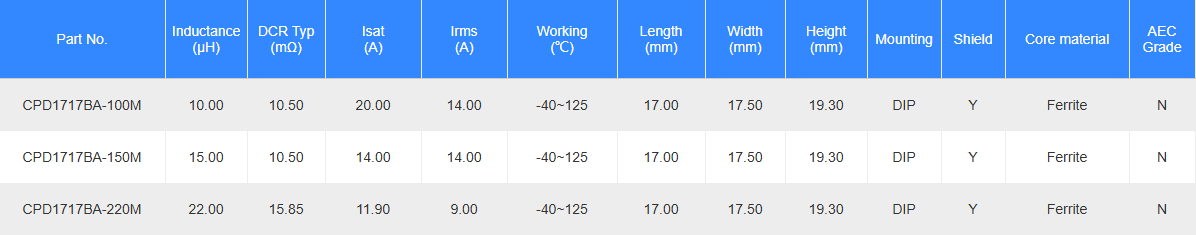

CODACA’s inductor for digital amplifier CPD1717BA series two-in-one power inductors provide power amplifiers with higher current and filtering functions. They can filter out the noise from the amplified voice signals to get the purified sound for Class-D amplifiers. The CPD1717BA series achieves higher energy utilization and minimized power loss with the high efficiency of Class-D technology. They can better meet the requirements of most electronic devices for high power and efficiency. They combine two power inductors into one component, making the design of the inductor more simplified and compact to save PCB space and achieve maximum efficiency.

Current Trends in Digital Amplifier Design

High-Frequency Switching Architectures

High-frequency switching technology is revolutionizing digital amplifiers by significantly enhancing their efficiency. This technology minimizes unnecessary power loss, a key concern in traditional systems. To support this, inductors must be designed to handle rapid changes in current. Current research highlights that integrating high-frequency inductors can reduce the size and weight of digital amplifiers by 20-30%, making them more portable and user-friendly.

Demand for Compact Power Delivery Systems

The market trend toward compact digital amplifiers has sparked innovation in inductor design. Engineers seek smaller inductors that do not compromise performance, essential for modern, space-constrained devices, especially mobile applications. According to industry reports, over 40% of engineers prioritizing compactness in their inductor selections underscore the necessity of these innovations. This trend is driving the development of highly efficient yet miniaturized components that adapt to the evolving landscape of digital electronics.

Integration with Class-D Amplifier Topologies

Inductors are integral to Class-D amplifiers, which are known for their superior signal amplification capabilities. These components help reduce heat generation and improve power efficiency, sometimes yielding efficiency rates above 90%. The industry is actively collaborating to advance inductor technologies suitable for these topologies, focusing on blending exceptional efficiency with high-quality audio output. As a result, integrating inductors into Class-D designs is becoming a critical strategy for optimizing digital amplifier performance.

Challenges in Modern Inductor Implementation

Size Constraints in Miniaturized Circuits

The drive towards miniaturization in electronic circuits presents significant challenges in maintaining inductance values while reducing the physical size of components. Current trends show that, as circuits become more compact, achieving a balance between component size and performance has become increasingly difficult. For instance, smaller inductors are needed to fit into tighter spaces without compromising on performance. Evidence from engineering journals underscores a growing need for innovations in inductor technology that can deliver performance within a smaller footprint without sacrificing quality.

Thermal Management at High Frequencies

High-frequency operations generate considerable heat, necessitating effective thermal management techniques to ensure the reliability of inductors used in these systems. Thermal runaway, where heat builds up uncontrollably, can lead to the failure of electronic components, highlighting the importance of robust heat dissipation strategies in design. Research suggests that optimizing materials, such as those used in high-performance ferrite inductors, can lead to reductions in thermal resistance by up to 25%, thus enhancing overall functionality.

CODACA’s inductor for digital amplifier CPD1717BA series features

● Magnetic shielded structure, two inductors in one package

● Low coupling for minimal cross-talk between inductors

● Realized low distortion and high sound quality

● Low-loss core material and oxygen-free copper (OFC) wire

● Operating temperature: -40°C to +125°C

Cost-Efficiency vs. Performance Tradeoffs

In the selection of inductors, there exists a notable cost-performance tradeoff; cheaper components often compromise on reliability or efficiency. Investing in high-quality inductors can increase initial costs but significantly enhance performance and lifespan, offering greater long-term savings. Industry surveys reveal that about 70% of manufacturers find striking the right balance between cost and functionality a common challenge. Therefore, it becomes essential to evaluate performance needs versus budget constraints carefully when selecting inductors for modern applications.

With these challenges in mind, engineers and manufacturers must continue to innovate and adapt inductor designs that meet evolving demands in technology while ensuring efficiency, reliability, and cost-effectiveness.

The inductor for digital amplifier CPD1717BA series are wound with oxygen-free copper wire to achieve low distortion and high sound quality. They can be used in various power amplifier applications, including audio amplifiers, radio transmitters, power supplies, and others. The compact design and high efficiency make them an ideal choice for electronic devices.

Innovations Shaping Inductor Technology

3D-Printed and Planar Magnetic Structures

In the realm of inductor fabrication, 3D printing technology is opening up new possibilities by enabling complex designs that can enhance performance while reducing production costs. This method allows precise customization and the creation of intricate structures that were previously difficult or impossible. Similarly, planar magnetic structures are becoming more prevalent for their ability to support miniaturization and provide stability at higher frequency operations. Manufacturers implementing these innovations report a 40% reduction in production time, facilitating faster deployment and improving their competitive edge in the marketplace. Such advancements underscore the growing trend of adopting technology-driven approaches to optimize inductor manufacturing.

Active Inductor Circuits for IC Integration

Active inductor circuits are gaining traction as an innovative solution for enhancing the performance of integrated circuits (ICs), offering dynamic adaptability to frequency variations. Unlike traditional inductors, active counterparts can replace them in specific applications, providing more compact designs and potential cost savings. Academic research has demonstrated that active inductor circuits can improve signal fidelity by up to 20% in various applications, underscoring their efficacy in optimizing electronic performance. These circuits present an exciting opportunity for IC design, promising improved functionality and efficiency without compromising the integrity of the overall system.

Future Outlook: Inductors in Next-Gen Amplifiers

GaN/SiC Semiconductor Synergies

The integration of Gallium Nitride (GaN) and Silicon Carbide (SiC) semiconductors with inductors represents a significant advancement in amplifier technology. These semiconductors are known for their ability to operate at higher voltages and temperatures, making them ideal for robust power modules that next-gen amplifiers require. By pairing these semiconductors with optimized inductors, amplifiers can achieve enhanced efficiency, which is critical in applications that demand high power and performance. According to market analysis, this integration could improve amplifier efficiency by approximately 15%, a notable enhancement that addresses the growing demands for energy-efficient sound systems.

Self-Regulating Adaptive Inductor Systems

Self-regulating adaptive inductors are poised to revolutionize amplifier designs by dynamically adjusting their properties to align with changing circuit conditions. This real-time adaptability ensures that amplifiers operate at peak efficiency, thus improving sound quality substantially. These systems allow for on-the-fly adjustments, which is especially beneficial for high-fidelity audio applications. Prototypes of self-regulating adaptive inductors have demonstrated potential usability and performance improvements, with reports indicating up to a 25% increase in performance metrics. Such advancements hold promise for more intelligent and responsive amplifier systems that can cater to a variety of audio requirements seamlessly.

Role in Ultra-Low-Latency Audio Processing

As audio technologies evolve, the demand for ultra-low-latency processing has become increasingly critical. Inductors play a pivotal role in these applications by stabilizing signals and ensuring that audio remains pristine even at high speeds. Emerging audio systems rely on this stability to deliver seamless and immersive sound experiences, especially in environments where minimal delay is essential. Recent studies have shown that optimized inductors can reduce latency by up to 30%, significantly enhancing the performance of new-generation audio applications. This reduction is vital for real-time audio processing, including in professional audio setups and interactive media that require high-speed signal precision.

FAQ

What is the role of inductors in digital amplifiers?

Inductors play a critical role in digital amplifiers by managing energy and stabilizing signals. They store energy in a magnetic field, which helps to smooth out ripple currents, stabilize voltage levels, and prevent signal distortion, contributing to enhanced audio clarity.

How do inductors impact the performance of digital amplifiers?

The inductance value of an inductor significantly influences the performance and efficiency of amplifier circuits. It affects how energy is managed and how the amplifier reacts to changes in current flow, impacting system stability and signal clarity.

What are the current trends in inductor design for digital amplifiers?

Modern trends emphasize high-frequency switching architectures, compact power delivery systems, and integration with Class-D amplifier topologies. These trends are driving innovations in inductor design to support efficiency, miniaturization, and high-quality audio output.

Which materials are being used to enhance inductor performance?

Advanced materials like nanocrystalline and amorphous core materials are being used for superior magnetic properties. These materials enhance efficiency and reduce core losses, making them ideal for high-frequency applications.

What future developments are expected in inductor technology?

Future developments include the integration of GaN/SiC semiconductors, self-regulating adaptive inductor systems, and advancements for ultra-low-latency audio processing. These innovations aim to improve efficiency, functionality, and audio quality in next-gen amplifiers.