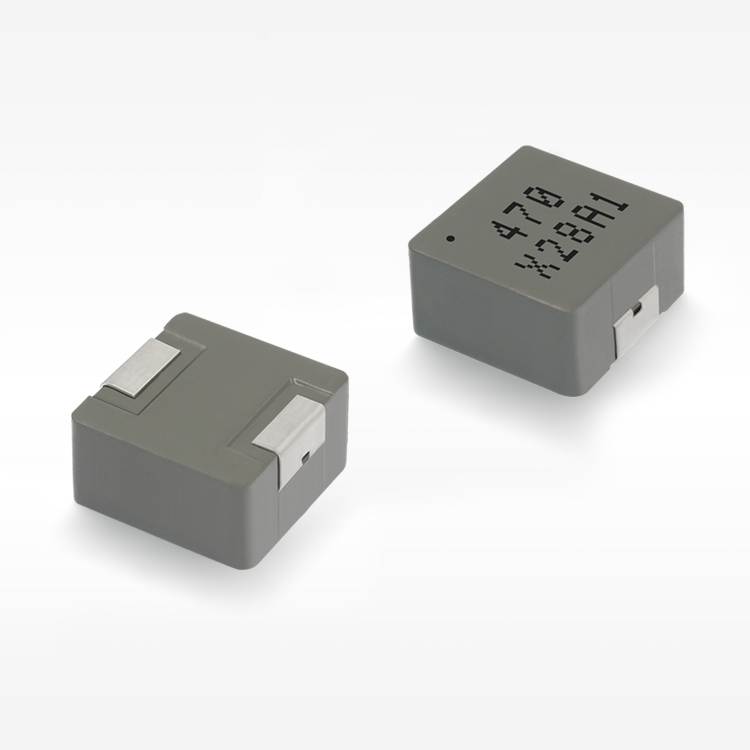

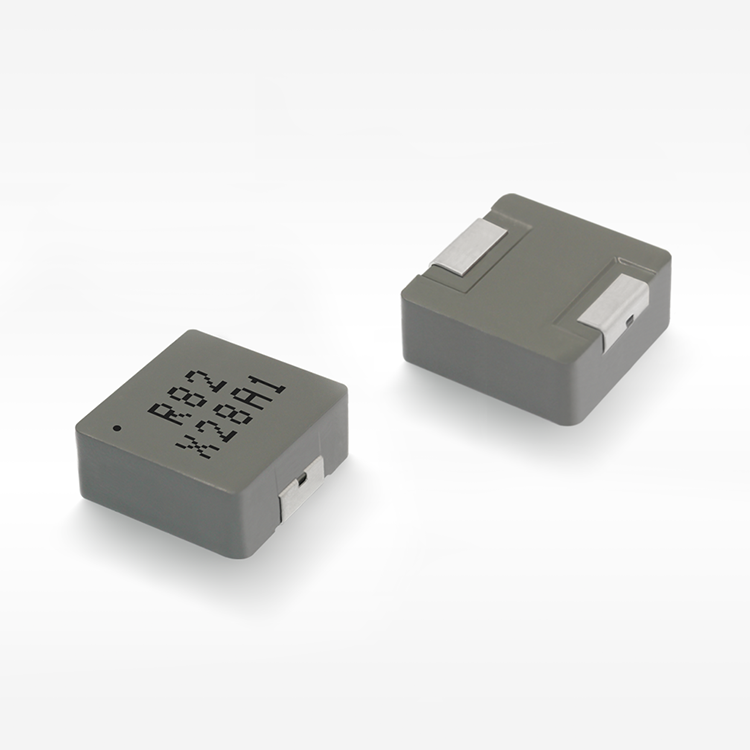

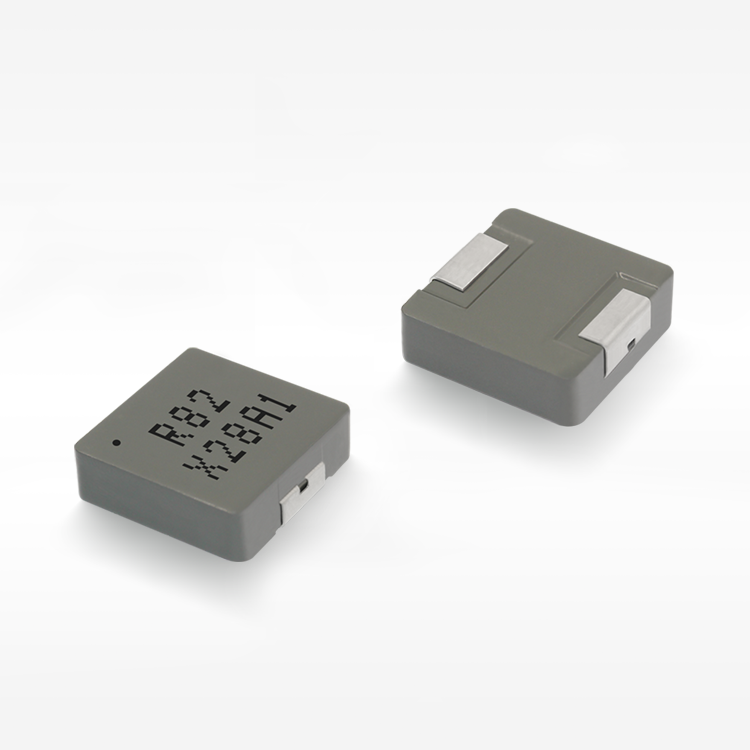

molding power choke for communication

The molding power choke for communication represents a critical component in modern electronic systems, specifically engineered to manage electromagnetic interference and ensure stable power delivery in communication devices. This specialized inductor utilizes advanced molding techniques to encapsulate ferrite cores and copper windings, creating a robust filtering solution that maintains signal integrity across various frequency ranges. The molding power choke for communication functions primarily as a line filter, suppressing unwanted noise and harmonics while allowing desired signals to pass through unimpeded. Its construction involves precision-wound coils secured within thermoplastic housings, providing excellent thermal stability and mechanical durability essential for communication applications. The technological features of the molding power choke for communication include high inductance values ranging from microhenries to millihenries, current handling capabilities from milliamps to several amperes, and frequency response characteristics optimized for communication bands. These components incorporate low-loss ferrite materials that minimize energy dissipation while maximizing filtering effectiveness. The molding process ensures consistent parameters across production batches, eliminating variations that could compromise system performance. Applications for the molding power choke for communication span telecommunications infrastructure, wireless communication systems, data transmission equipment, and consumer electronics. These inductors prove essential in switching power supplies, DC-DC converters, and filter circuits where clean power delivery directly impacts communication quality. Network equipment, mobile devices, and IoT sensors rely on molding power choke for communication to suppress switching noise and prevent interference between circuits. The compact form factor achieved through molding techniques enables integration into space-constrained designs while maintaining high performance standards. Temperature stability and long-term reliability make the molding power choke for communication suitable for demanding environments where consistent operation is paramount for maintaining communication links.