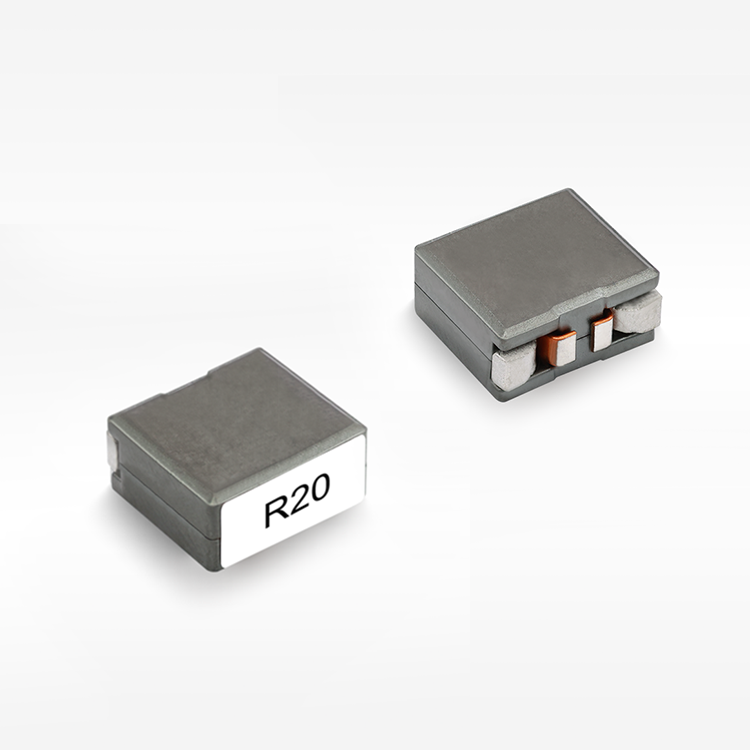

high current shielded power inductors

High current shielded power inductors represent a critical component in modern electronic systems, designed to handle substantial electrical currents while maintaining electromagnetic compatibility and operational efficiency. These specialized inductors feature a magnetic shield that encapsulates the inductor core, preventing electromagnetic interference from affecting surrounding components and circuits. The primary function of high current shielded power inductors involves energy storage and release in switching power supplies, DC-DC converters, and voltage regulators. Their technological architecture incorporates ferrite or powdered iron cores with carefully engineered winding configurations that optimize magnetic flux distribution. The shielding mechanism utilizes magnetic materials that create a closed-loop magnetic path, effectively containing the magnetic field within the component structure. This containment reduces radiated electromagnetic emissions and improves overall system performance. Advanced manufacturing techniques ensure these inductors can accommodate currents ranging from several amperes to hundreds of amperes, depending on the specific application requirements. The compact form factor achieved through innovative design methodologies allows engineers to maximize power density in space-constrained applications. Temperature stability remains a crucial characteristic, with modern high current shielded power inductors operating reliably across wide temperature ranges while maintaining consistent electrical parameters. Applications span across automotive electronics, telecommunications infrastructure, renewable energy systems, industrial automation, and consumer electronics. In automotive applications, these components support electric vehicle charging systems, engine control units, and advanced driver assistance systems. Telecommunications equipment relies on high current shielded power inductors for base station power supplies and network infrastructure components. Renewable energy installations utilize these inductors in solar inverters and wind power conversion systems, where reliability and efficiency directly impact energy harvesting effectiveness. The integration of advanced materials and precision manufacturing processes ensures these inductors deliver consistent performance while meeting stringent electromagnetic compatibility standards required in modern electronic designs.